Wires insulated with polyurethane varnishes have good solderability at 375°C. Special formulations result in excellent crack and pinhole resistance. These wire enamels are mainly used in small transformers, timers, relays, small motors, solenoids, clock coils, flyback transformers, magnetic heads or automotive coils such as relays and ignition coils.

Solderable polyesterimide wire enamels can be soldered even at temperatures above 450 °C in some cases. The coated magnet wires have good elasticity as well as good dielectric and mechanical properties. These coatings are particularly suitable for small electric motors to connect the windings to the collector. Polyesterimide wire enamels are often used on winding wires for relays, small transformers, small motors, circuit breakers, ignition coils, magnetic switches and in automotive applications.

.jpg)

THEIC polyesterimide wire enamels are very heat resistant and have very good mechanical, electrical and chemical resistance. These wire enamels are commonly used on wires in electric motors, refrigeration equipment, transformer windings and fluorescent lamp ballasts.

Polyamideimide wire enamels can be used as either single or double enamels; both options provide excellent mechanical properties and the highest chemical resistance. In addition to the classic polyamideimide coating, wire enamels with integrated lubricant for increased winding speed are also available. These products are used specifically for coating wires in electric motors, refrigeration systems, transformer windings, solenoid valves and ballasts for fluorescent lamps.

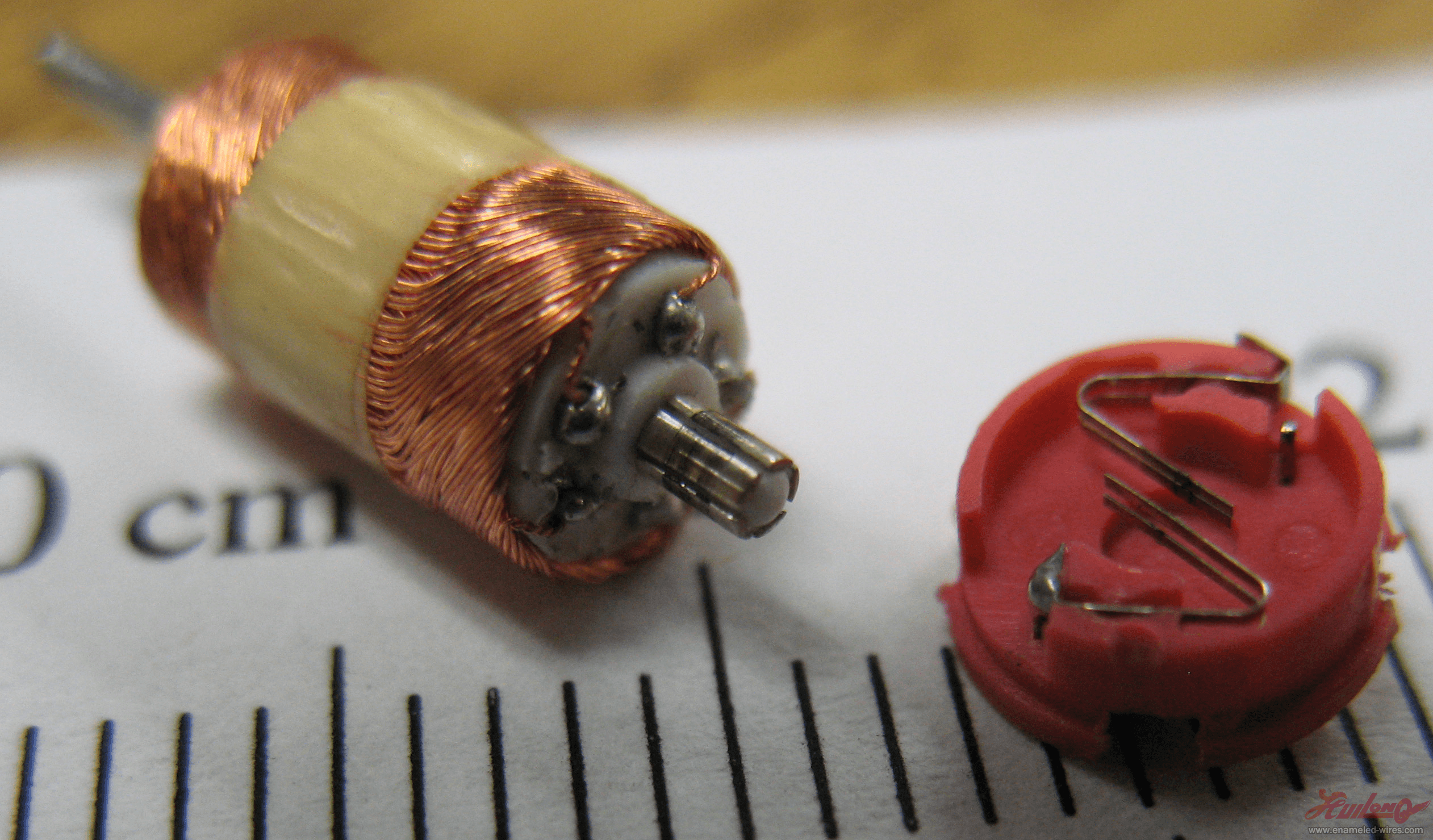

Self-bonding enamel is mainly used for coils in measuring instruments, voice coils (such as loudspeakers), small motors and sensors.

A further type of wire is self-bonding enamelled wire, which contains a second layer of enamel. However, this so-called self-bonding overcoat is not used for insulation, but for the mechanical stability of a coil. The self-bonding enamel layer is based on epoxy resins, polyvinyl butyral or polyamide. In addition to the technical requirements, the preferred bonding process is decisive for the selection. In the bonding process, the windings are thermally or chemically bonded together, for example for self-supporting windings such as air core coils. Likewise, different types of self-bonding enamel are available depending on the continent.

Baked enamel wires, like the enamelled wires mentioned above, are not only available with copper as the conducting material, but also with alloys, aluminium or copper-clad aluminium, among others, for lightweight coils or high-strength conductors for better durability. Self-bonding enamel is mainly used for coils in measuring instruments, voice coils (such as loudspeakers), small motors and sensors.

Different Types Of Reel and Sp

Different Types Of Reel and Sp

The Critical Role of Winding C

The Critical Role of Winding C

PEW/155 QZL-1 Degree 0.25mm- 5

PEW/155 QZL-1 Degree 0.25mm- 5

Magnet Wire Information

Magnet Wire Information