Buyers import enameled wire from China, what are the most afraid of the following? How to avoid it later? How to do the plan?

What are the most afraid of buyers buying enameled wire from China?

Precautions for buyers to import enameled wire from China

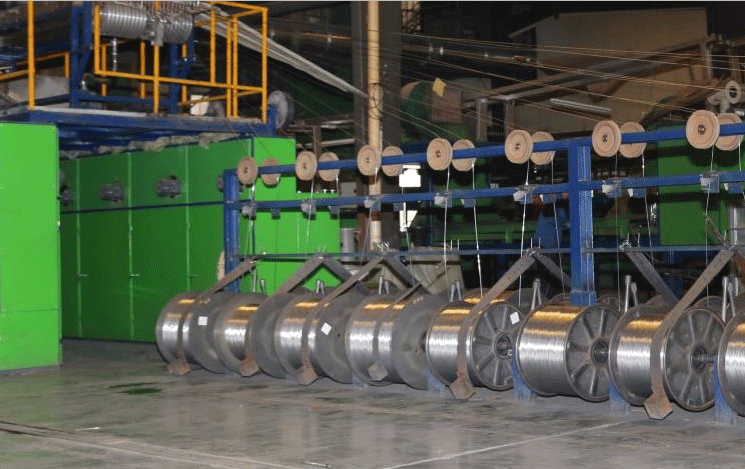

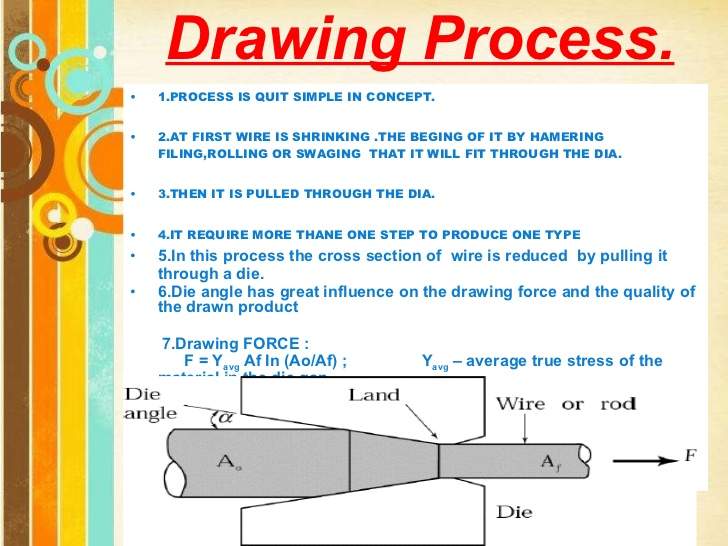

Enamelled production process

Enamelled production quality control

More than 20 companies in China have introduced nearly 200 enameled wire production lines from Austria, Japan, Italy and Taiwan, and introduced more than 700 enamelling machines. The total production capacity of the sets and testing instruments is about 300,000 tons. Among them, the equipment produced by Austrian MAG Company is the most, accounting for more than 80%, which makes the product structure, equipment level and manufacturing technology of China's enameled wire industry rapidly improve and close to or reach. The international advanced level has greatly shortened the gap between China and the international enameled wire industry.

From the product structure, product quality and market supply scale, it basically meets the demand for enameled wire in emerging industries such as domestic appliances. The national enameled wire production expanded from 50,000 tons in 1980 to 100,000 tons in 1990. In 2000, the national production and sales volume exceeded 300,000 tons, thus entering the second place in the world of enameled wire production and demand.

After more than 50 years of development, China's enameled wire industry has formed a production capacity of over 700,000 tons.

Keywords: Magnet wire, enameled wire, coil, copper wire, aluminum wire, Flat wire, ECCA, Copper clad Aluminum

Philippine Clients Highly Prai

Philippine Clients Highly Prai

Huilong Company Conducts Safet

Huilong Company Conducts Safet

Huilong to Showcase Innovative

Huilong to Showcase Innovative

What is enameled aluminum wire

What is enameled aluminum wire