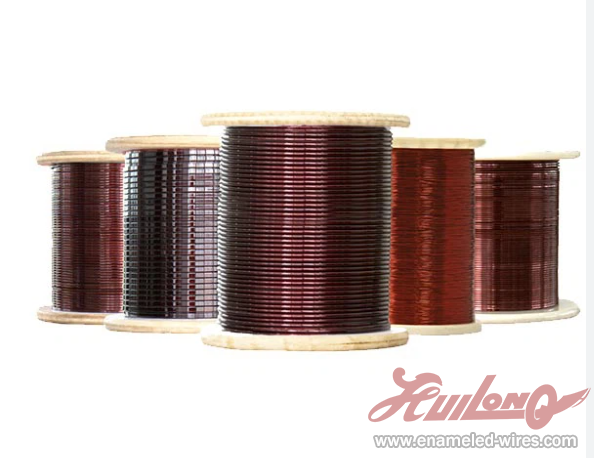

Enamel copper wire (also called magnet wire) is a copper wire coated with a thin insulation layer (typically enamel). At Vidya Wires, we offer various enameled copper winding wires with excellent tensile strength, elongation, etc. These enameled coatings insulate and safeguard the wire from moisture and chemical exposure.

The most enameled coating types used in copper wire include those from thermal class 105 ℃ to 240 ℃. These include polyvinyl acetal, modified polyester, polyester-imide, polyamide-imide, aromatic polyimide, polyurethane, corona resistance wire suited for different applications across the industrial world.

Each enamel coating offers unique benefits, making it suitable for different applications. These include general electrical use to more sophisticated industrial setups where heat, mechanical stress, and environmental factors prove critical.

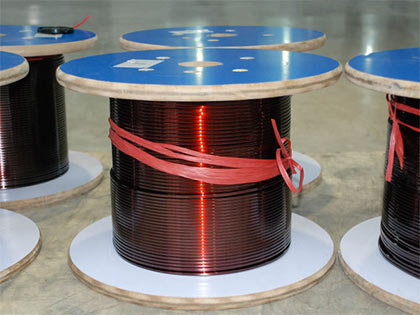

The material is electrolytically refined copper and fully annealed to optimize the benefits of customization in hermetic applications, electrical motors, transformers, switchgear, consumer and industrial electronics, auto electrical, refrigerators, ACs, home appliances, windmills, generators, EV – motors, pumps, fans, etc.

Enameled copper wires offer a range of advantages. Of course, the wire’s efficiency also depends on the winding wire manufacturer you choose. However, generally speaking, an enameled copper wire offers the below benefits.

· High Ductility: Copper alloy’s elongation rate of 20~40 percent contributes to the high ductility of enameled copper wires.

· Low Resistivity: Enameled copper wires have an electrical resistance 1.68 times higher than the copper wire cable.

· Anti-Fatigue: Copper is not easily breakable. It has an elasticity of up to 1.8 times higher than aluminium.

· Low Voltage Loss: The low resistivity of the copper wire lets the same current flow in the same section. Copper cables have a smaller voltage drop. So, the same transmission distance can ensure better voltage quality.

· Low Electrical Loss: Again, the low resistivity of copper contributes to a lower electrical loss than aluminium wires.

· Low Heat Generation: Copper enameled wires of the same section, and under the same current, generate less heat than aluminium wires. Hence, the enameled copper wires are operationally much safer.

Here are some reasons making HuiLong Wires one of the most trustworthy and enameled copper winding wire manufacturers in India.

· Uncompromised Quality: For us, quality is of paramount significance. Accordingly, each of the enameled copper wire we manufacture undergoes stringent and multiple quality checks under various environments to test and assure its quality across various parameters like strength, resistance, ductility, etc.

· Qualified and Experienced Resources: We nurture a team of experienced and expert product designers and production resources who resonate with the company’s aim and vision to deliver customer excellence and maintain its position as one of the leading enameled copper winding wire manufacturers in India.

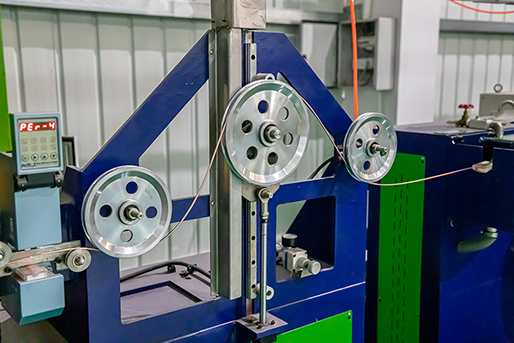

· High-Tech Manufacturing Infrastructure: We boast a state-of-the-infrastructure, enabling us to manufacture enameled copper wires under a controlled environment meeting all of the customer’s expectations and application’s needs.

· Comprehensive Customer Support: As one of the leading copper enameled wire manufacturers in India, our support and responsibility do not end with manufacturing. Instead, it extends to various other areas like maintenance, technical support, warranty replacements and more.

Enameled Aluminum Wire

Enameled Aluminum Wire

Enamelled Copper Wire

Enamelled Copper Wire

What are the characteristics a

What are the characteristics a

.jpg) Polyester or polyesterimide ov

Polyester or polyesterimide ov