Polyester or polyesterimide overcoated with polyamide-imide enamelled round copper wire, class 200, is a highly specialized wire designed for high-performance applications. This wire combines the benefits of multiple insulating materials, providing exceptional properties. It suitable for various demanding environments.

The base materials for this type of enamelled wire include polyester or polyesterimide and polyamide-imide. Together, these materials ensure the wire operates efficiently at temperatures up to 200℃ (Class 200).

.jpg)

This is extensively used wire enamel with excellent thermal properties, class 180 or above. Known for good flexibility, adhesion, and electrical properties.

Adequate thermal stability. These coatings can typically withstand temperatures up to 180℃, making them suitable for high-temperature applications.

Offers superior thermal stability, abrasion resistance, and chemical resistance. Excellent mechanical-property retention at elevated temperatures.

It can endure temperatures up to 220℃ or higher, extending the wire’s operational range. It offers exceptional resistance to a wide range of chemicals, including solvents and corrosive agents.

This Part of lEC 60317 specifies the requirements of enamelled round copper winding wire of class 200 with a dual coating.

IEC 60317-13 is a standard within the IEC 60317 series, which sets out specifications for various types of winding wires.

Part 13 specifically deals with enamelled round copper wire that has a base coating of polyester or polyesterimide. And it has a top coating of polyamide-imide. It is classified as Class 200. It is suitable for continuous operation at temperatures up to 200℃.

The underlying coating is based on polyester or polyesterimide resin, which may be modified providing it retains the chemical identity of the original resin and meets all specified wire requirements. The superimposed coating is based on polyamide-imide resin.

NOTE A modified resin is a resin that has undergone a chemical change, or contains one or more additives to enhance certain performance or application characteristics.

Resistance to refrigerants: The percentage of extract able matter shall not exceed 0.5%.The requirement for breakdown voltage shall be 75% of the minimum specified value.

Flexibility and adherence: The constant K used for the calculation of the number of revolutions for the peel test shall be 110 mm.

Heat shock: The minimum heat shock temperature shall be 220℃.

Cut-through: No failure shall occur within 2 min at 320℃.

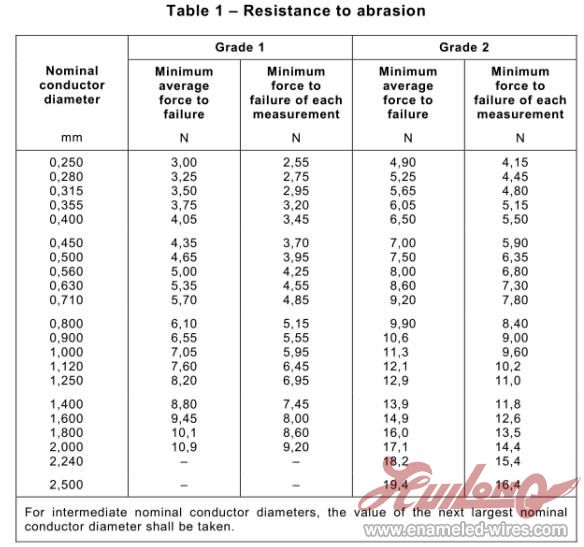

Resistance to abrasion (nominal conductor diameters from 0,250 mm up to and including 2,500 mm)

The wire shall meet the requirements given in Table 1.

IEC 60317-13 provides detailed specifications for round copper wires enamelled with polyester or polyesterimide base coats and polyamide-imide overcoats. It classified as Class 200. These specifications ensure the wire’s reliability in applications requiring high thermal, mechanical, and chemical performance. Adherence to these standards guarantees the wire’s efficiency and longevity in demanding industrial and automotive applications.

Advantages and Benefits

1.High Temperature Resistance: The primary advantage of class 200 wire is its ability to operate continuously at temperatures up to 200℃.

2.Reduced Risk of Thermal Degradation: The polyamide-imide overcoat significantly enhances the thermal stability of the wire.

3.Resistance to Solvents and Chemicals: The polyamide-imide overcoat provides excellent resistance to a wide range of chemicals and solvents.

4.Corrosion Resistance: Enhanced resistance to corrosive environments prolongs the lifespan of the wire.

5.Abrasion Resistance: The polyamide-imide layer offers superior abrasion resistance. It is protecting the wire from physical wear and tear during installation and operation.

6.High Insulation Resistance: Excellent insulation. The enamelled reducing the risk of electrical faults and ensuring efficient energy transfer.

7.Dielectric Strength: The high dielectric strength of the polyamide-imide overcoat prevents electrical breakdown. It is enhancing the safety and reliability of the wire in high-voltage applications.

8.Extended Service Life: The combination of high thermal stability, chemical resistance, and mechanical strength contributes to the wire’s extended service life.

In short, Polyester or polyesterimide overcoated with polyamide-imide enamelled round copper wire, class 200, combines excellent thermal stability, chemical resistance, and mechanical strength. It is a preferred choice in demanding applications across various industries.

It offers a range of advantages that make it indispensable in high-performance electrical and electronic applications. Its superior thermal stability, chemical resistance, mechanical strength, and electrical properties ensure reliable and efficient operation in demanding environments.

Enameled Aluminum Wire

Enameled Aluminum Wire

Enamelled Copper Wire

Enamelled Copper Wire

What are the characteristics a

What are the characteristics a

.jpg) Polyester or polyesterimide ov

Polyester or polyesterimide ov