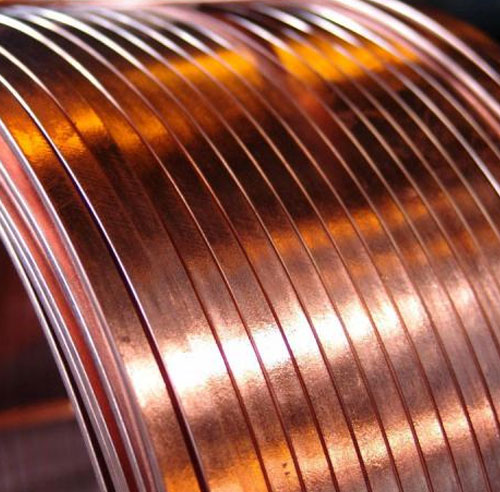

Wire enamels are applied on copper and aluminum round and flat wires used in motors, transformers, generators and electrical measuring instruments. They are cured onto the wires with heat. The resulting coating’s main function is electrical insulation. Wire enamels are also described as primary insulation. The coated wires are sometimes called “magnet wires”.

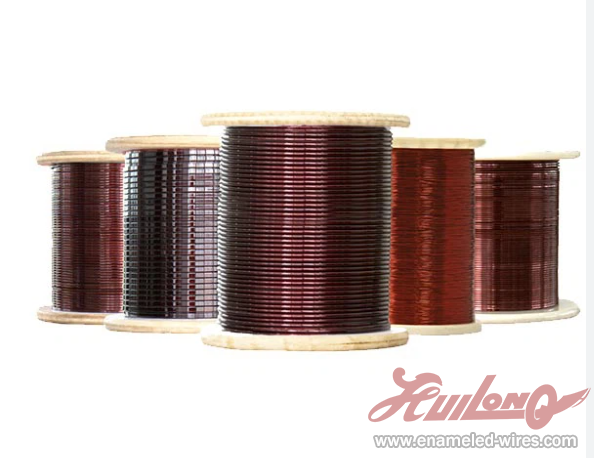

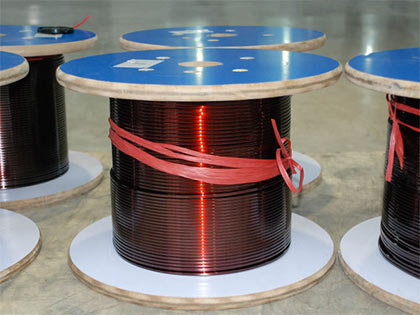

Wire enamels are applied to copper and aluminum wires in up to 30 layers. This provides electrical insulation and helps the windings from short-circuiting. These wire enamels must also have very good chemical and thermal resistance, must adhere very well to copper or aluminum wire, and have outstanding mechanical stability.

In some instances, for example when used in inverter-driven electric motors, the appropriate insulation layer should resist possible partial discharges, which can cause the motor to short-circuit and fail.

The wires that are coated vary greatly depending on their use. Some may be smaller than the diameter of a single human hair – in electronic components of watches for instance. But in heavy electric motors in wind generators, the diameter of round or flat wires can measure up to several millimeters.

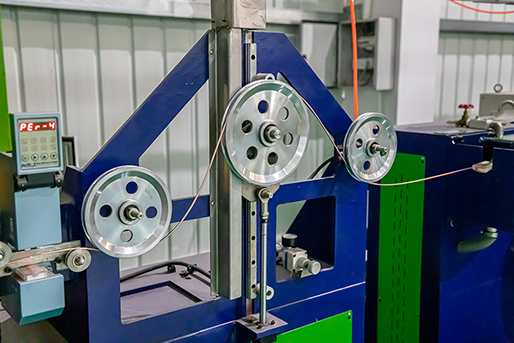

The wire enamel is applied differently depending on the shape and diameter of the wire to be coated. Horizontal or vertical application, or application with dies or with felts, are typical wire coating methods.

Thanks to Axalta’s close relationship with the international magnet wire industry, the company is able to develop new technologies and manufacturing processes continually, as well as adapt its product portfolio to meet the ever-changing market requirements. This also means that Axalta has created custom wire enamel solutions in particular for motor applications that have helped to improve and to optimize specific customers’ operational performances.

Chemically, the wire enamel range consists of polyurethane, polyester, polyesterimide, polyamide-imide. The range of solids content starts at nearly 8% and ends at 60% (1g/1h/180°C), and the viscosity range is between 30 and 60000 mPas (23°C).

Enameled Aluminum Wire

Enameled Aluminum Wire

Enamelled Copper Wire

Enamelled Copper Wire

What are the characteristics a

What are the characteristics a

.jpg) Polyester or polyesterimide ov

Polyester or polyesterimide ov