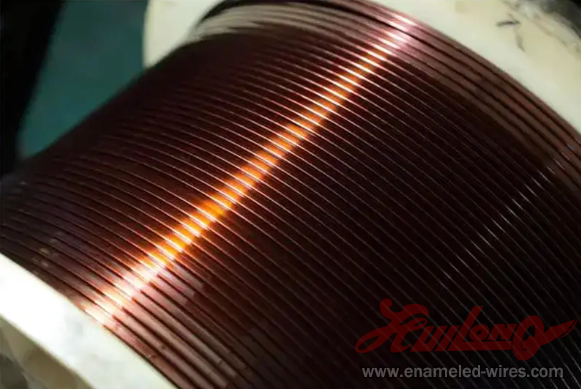

Flat wire production line is characterized by its rectangular cross-section and a smooth, bright surface, cold rolled and cold drawn flat wiremaking it suitable for various applications in industries such as construction, automotive, and manufacturing.  The edges of flat wire can either adopt a natural arc shape, which provides flexibility in certain uses, or a sharp acute angle shape, offering enhanced precision for applications requiring tighter tolerances. The production process is primarily completed through cold rolling or cold drawing techniques, which not only improve the wire’s mechanical properties but also ensure a consistent thickness and surface finish. These attributes make flat wire an essential component in the creation of products ranging from springs to decorative elements.

The edges of flat wire can either adopt a natural arc shape, which provides flexibility in certain uses, or a sharp acute angle shape, offering enhanced precision for applications requiring tighter tolerances. The production process is primarily completed through cold rolling or cold drawing techniques, which not only improve the wire’s mechanical properties but also ensure a consistent thickness and surface finish. These attributes make flat wire an essential component in the creation of products ranging from springs to decorative elements.

Stainless Steel – Known for its strength and excellent corrosion resistance, stainless steel flat wire is a popular choice for various demanding applications, especially in harsh environments.

High-Performance Alloys – These alloys offer superior fatigue resistance, strength, and corrosion resistance, making them ideal for critical applications that require durability under extreme conditions.

Nitinol – Valued for its unique shape memory and superelastic properties, Nitinol is commonly used in applications where flexibility and recovery are essential, such as medical devices.

Titanium – Renowned for its high strength-to-weight ratio and biocompatibility, titanium is often used in medical, aerospace, and high-performance engineering fields.

Carbon Steel: It is one of the most commonly used materials in construction and manufacturing due to its excellent strength, hardness, and versatility. The properties of carbon steel can vary significantly based on its carbon content.

Flat wire is characterized by its rectangular cross-section and a smooth, bright surface, making it suitable for various applications in industries such as construction, automotive, and manufacturing. The edges of flat wire can either adopt a natural arc shape

Dedicated flattening machines, also known as wire flatteners or flat wire rolling mills, are specifically engineered to transform round metal wire into flat wire. These machines utilize a series of rollers to achieve the desired flat shape and precise thickness. They are widely used in applications that demand uniform flatness and superior surface quality.

Dedicated flattening machines, also known as wire flatteners or flat wire rolling mills, are specifically engineered to transform round metal wire into flat wire. These machines utilize a series of rollers to achieve the desired flat shape and precise thickness. They are widely used in applications that demand uniform flatness and superior surface quality.

Wire Rolling Mills

A rolling mill containing two rollers is also known as a two-high cold rolling mill. Its purpose is to process metals from round wires to flat shape wires. The Sky Bluer Industries Rolling Mills offer a wide variety of different options to meet a wide range of multiple applications in a variety of different industries.

Cold Rolling Machines for Produce Best Flat Wires

Cold drawing machines pull the wire through a series of drawing dies, shaping it into a flat profile from round wire or round bar. This process not only improves the wire's strength but also enhances its surface finish. Cold drawing is particularly effective for smaller diameter wires, delivering exceptional dimensional accuracy.

Different Types Of Reel and Sp

Different Types Of Reel and Sp

The Critical Role of Winding C

The Critical Role of Winding C

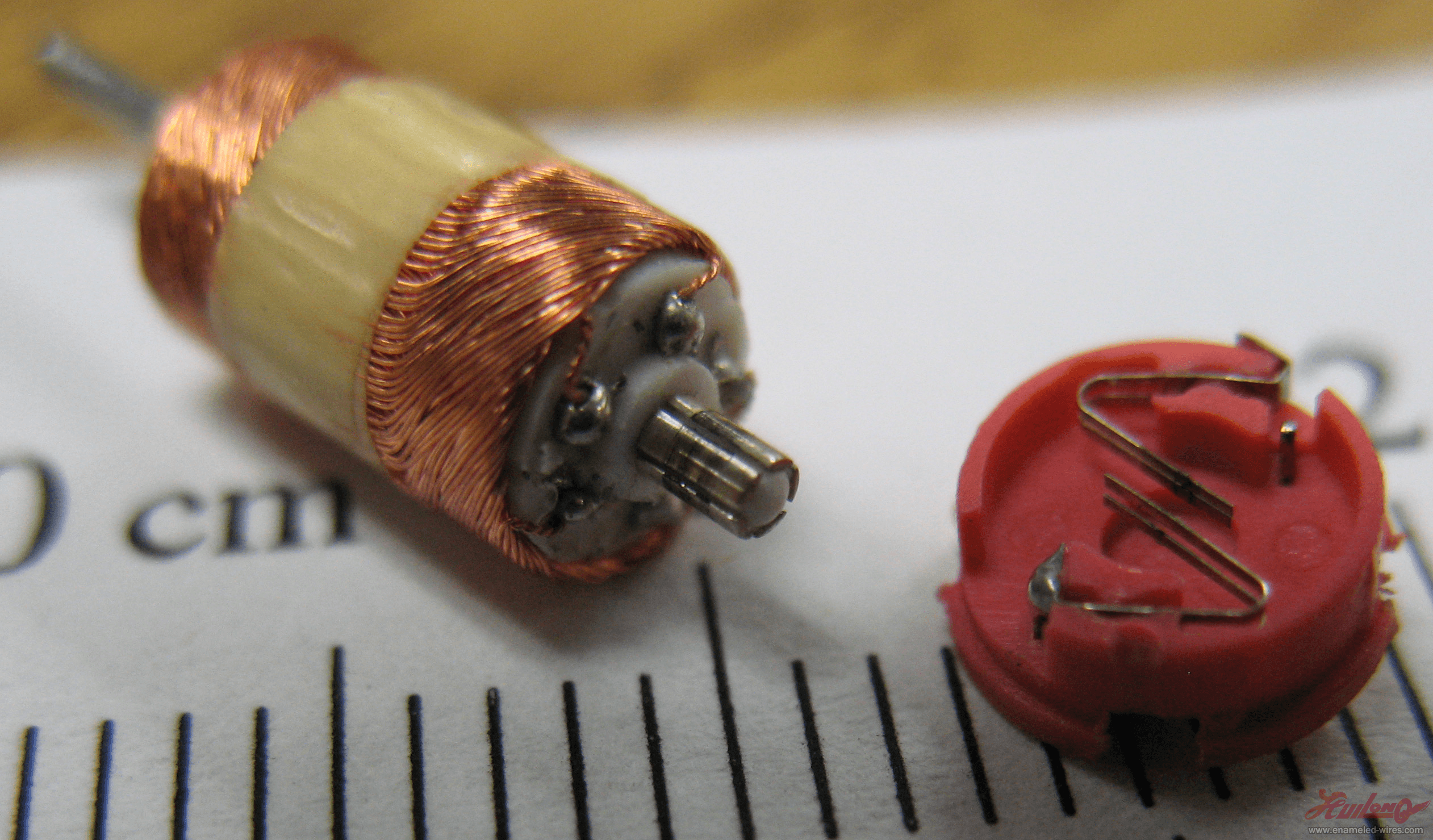

PEW/155 QZL-1 Degree 0.25mm- 5

PEW/155 QZL-1 Degree 0.25mm- 5

Magnet Wire Information

Magnet Wire Information