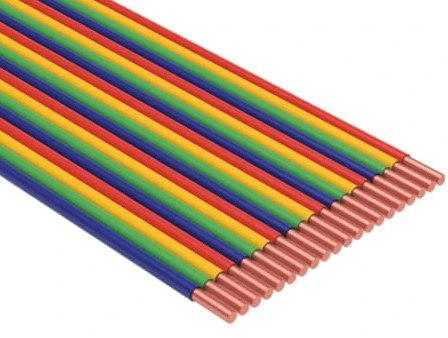

Huilong Enameled Wiresmagnet wire allows you to have two or more parallel bonded magnet wires insulated and color coded to your specifications.

Where constant alignment of multiple strands is an advantage, Enameled Wiresmagnet wire is the right choice. Its parallel-bonded, color-coded construction offers benefits for many applications.

Engineers should specify Enameled Wireswhen concerned with space, weight, and reliability. Where consistent capacitance and impedance characteristics are required, Enameled Wiresmagnet wire outperforms windings using two separate magnet wires.

Production users benefit from increased layer winding speeds, tighter windings that deliver more power in less space, reduced labor, and handling. Color coding assists in conductor identification and reduces termination errors.

Huilong Wire Industries custom manufactures Multifilar® magnet wire to assure flat, parallel construction in sizes AWG 16 and finer, and up to 20 conductors wide in some sizes.

Ten insulation colors are offered in polyurethane and poly-nylon films. Red, green, and natural are standard for all film types.

| Bond Code NO. | Bonding Coat (Operating Temperature) | Solvent* |

|---|---|---|

| 1 | Polyvinyl Butyral (105°C) | Alcohol |

| 2 | Nylon (105°C) | None |

| 3 | Epoxy (130°C) | MEK or Acetone |

| 4 | Polyester (130°C) | None |

| 5 | Polyamide (165°C) | None |

| 6 | Polyimide (ML) (240°C) | None |

* Nylon & ML are thermoset insulations which do not activate with either heat or solvent.

** Bonding films can be softened and removed by immersion in the solvent noted, except nylon, polyester, polyamide, and ML which are non-soluble. Wiping with a soft cloth dampened with solvent may be necessary to separate wires. Finished wire thermal class based on the underlying enamel of the individual strand.

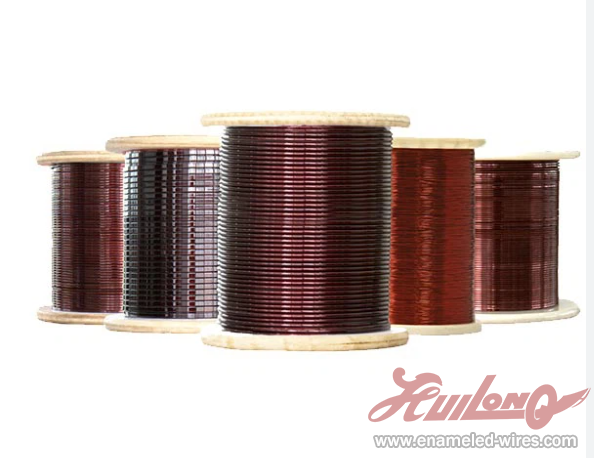

Enameled Aluminum Wire

Enameled Aluminum Wire

Enamelled Copper Wire

Enamelled Copper Wire

What are the characteristics a

What are the characteristics a

.jpg) Polyester or polyesterimide ov

Polyester or polyesterimide ov